Categories

Latest blog

Parts Cleanliness Types of Particulate Matter

Jul 20 , 2022Parts Cleanliness Types of Particulate Matter

Particulate Pollutants

Particulate contaminants are solid small particles or oil film contaminants that remain on the surface of parts. Particulate contamination can be generated during processing or introduced through supplier parts, packaging and logistics. During assembly, residual particles can enter the engine or transmission. Cause serious damage and greatly shorten the life of the product, especially hard metal particle contamination.

Surface Cleanliness

Surface cleanliness refers to residual contaminants on the surface of parts. To describe the state of cleanliness, the number, size and composition of residual contaminants and particles were determined. In upstream and downstream supply chain relationships, customers define thresholds for component contamination. And require suppliers to regularly test and measure strictly within the threshold range.

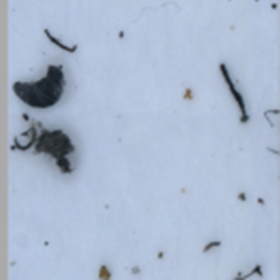

Types of Residual Particulate Matter

Non-Metal

Non-metallic elements do not have a shiny surface when they are solid, but different elements have different colors. Non-metallic elements are black, while metals are white. There are obvious differences in the hardness of non-metals. For example, non-metals are very soft and metals are the hardest. Non-metals are brittle and have a lower density than metals. The impact of non-metallic particles on components is not the greatest, but it cannot be ignored.

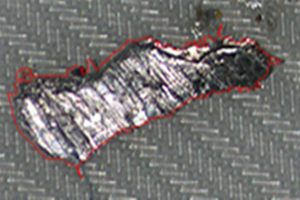

Metal

The hardness of metal particles depends largely on their material. The development of metal particle industry in general life has a lot to do with metal particles. Compared with non-metallic particles, metal particles are more shiny and hard, and metal particles cause great damage to parts (wear, electrical conductivity, blockage, etc.).

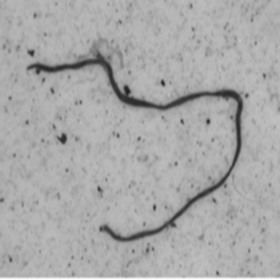

Fiber

Fibers often come from different sources—for example, work clothes, rags, or lab dust. Textile fibers generally do not have a significant impact on the functionality of technical components. Therefore, when evaluating cleanliness inspections, they should be identified and counted separately. Fibers have an elongated shape. The ratio of length to width is called fiberity and must be in the range of 10:1 to 20:1 (depending on the standard used). This means that the fibers must be significantly elongated (compared to other fiber measurements, such as the asbestos test, in which each fiber is as straight as a needle, but only has a 3:1 degree of fiber).