Excellent high temperature resistance

Suitable for pre-filtration in solution

Resistant to curling and deformation

Suitable for automotive parts cleanliness testing

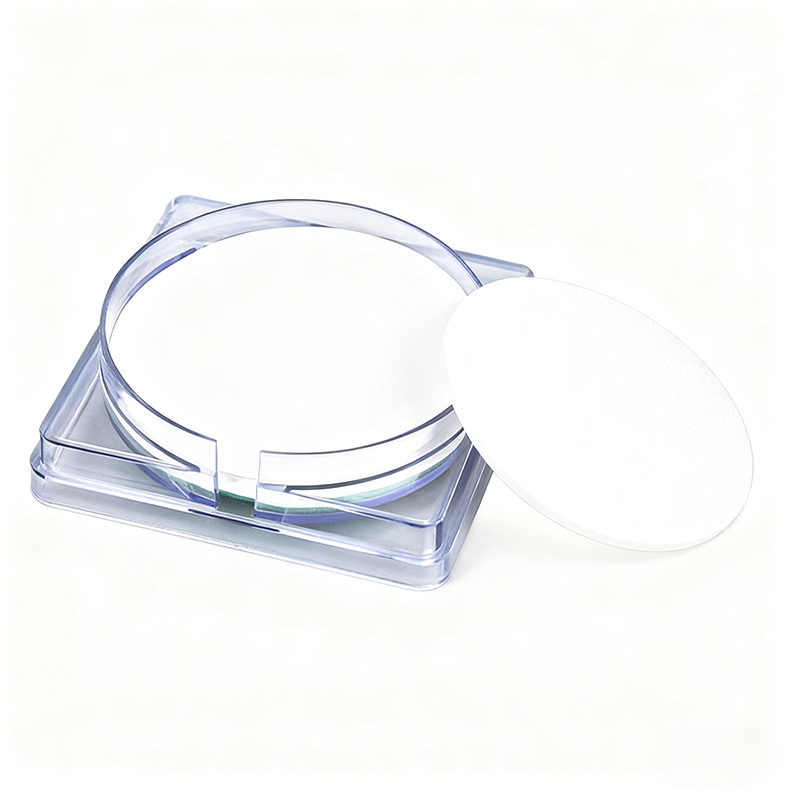

Description:

Nylon filter membranes for cleanliness testing are crucial quality control tools for technical cleanliness in precision filtration applications such as automotive parts, liquid cooling systems, and the medical industry. Cleanliness directly impacts production performance. Particles are trapped on the membrane surface and analyzed for size, weight, and composition using methods such as weighing and instrumental analysis.

What factors should be considered when selecting a cleanliness testing membrane?

1. Chemical compatibility with common cleaning agents.

2. Whether the membrane curls during the drying process after filtration?

This phenomenon is related to the shrinkage of the membrane material and the membrane manufacturing process.

3. The membrane maintains constant weight easily. The difference between the weight before and after filtration should be less than 0.5mg.

4. Mixed cellulose membranes are not recommended for components with excessive grease.

5. Gridded membranes may reflect light during microscopic particle counting. It is recommended to use a cleanliness analyzer with a filter to avoid misinterpreting gridded light as metal particles, which could reduce sample quality.

Features:

Organic nylon filter membrane

Filter accuracy: 0.2μm

Smooth surface, free of bubbles, impurities, or defects

Resistant to most organic solvents

In accordance with technical cleanliness standards ISO 16232 and VDA 19