Reliable Component Cleanliness Extraction Equipment

Ease of operation

Controlled extraction environment (laminar flow cabinet)

Programmable setting capabilities

Less human errors involved

No risk from environmental cross contamination

Reduced risk of operator contamination

Fit your available space and size of components

CC767 Component Cleanliness Cabinet

Accurate, Reliable, Repeatable Component Cleanliness Extraction

|

Summary

The equipment adopts a special touch screen control system and professional measurement and control software to display the working status of the equipment in real time. The cleaning pressure and flow are adjustable. With different cleaning nozzles, it can quickly and conveniently clean the cavity channels, blind holes, and the entire surface of the parts. Widely used in the cleanliness inspection of various auto parts. Meet ISO16232-2007, VDA19, GB/T3821-2005 and other international and domestic standards, and meet the cleanliness testing standards of major automobile factories such as Volkswagen, GM, Ford, etc

Applications

CC767 Component Cleanliness Cabinets are widely used for particle extraction and sample preparation when testing the surface cleanliness of various auto parts. For example: engine block, cylinder head, gear, crankshaft, connecting rod, camshaft, valve, piston, rocker arm, transmission shaft pin, oil pump, water pump, turbocharger, tubing oil circuit and other parts and assembly cleanliness Detection.

Features

Pressure jet cleaning area and function

The cleaning chamber of the cleaning extraction machine is made of 304 stainless steel seamlessly processed and molded, and polished to make the inner surface of the 8K mirror surface to ensure that the cleaned particles are collected on the filter membrane. The pressure jet cleaning uses a pressure cleaning spray gun. Manually control the spray gun to wash the surface of the part.

Inside of the cleaning chamber.

Workpiece supporting and spray gun.

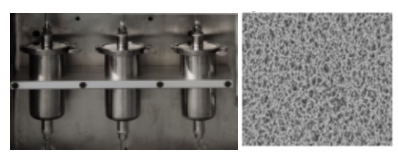

Online filtering and sample preparation

The cleaning agent after cleaning the parts passes through the online filter, which can realize synchronous automatic cleaning and filtering of samples, and timely collect the particle contaminants on the surface of the parts in the cleaning solution to the surface of the detection filter membrane. The equipment is equipped with a one-key three-stage particle filtration collection device as standard, and three-stage filter membranes with different pore sizes can be selected at the same time according to the needs, so as to collect particles according to the particle size range, so that the particles are more evenly distributed on each filter membrane. Accurately perform particle size image analysis, convenient for size measurement of large and small particles, and statistical analysis of the number of particles of different grades;

360-degree self-cleaning cleaning device

This cleaning extraction machine is equipped with a 360-degree rotating cleaning nozzle without dead ends; before cleaning and extracting the product, the blank value of the equipment needs to be tested. Only after the blank value of the equipment is qualified can it be used to test the surface cleanliness indicators of the parts. The equipment is testing the cleanness of the parts. Before temperature, use high-pressure and large-flow cleaning agent to spray 360-degree non-dead-angle spray on the cleaning chamber wall, so that the self-cleaning degree of the cleaning equipment meets its related standards, that is, the blank value index meets the VDA19 or ISO16232-3 standard, and the blank value ≤0.3mg/ 10um.

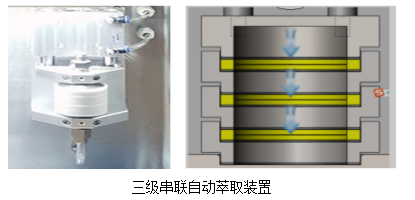

Multi-stage filter circulation device and function of cleaning agent

The equipment uses a special cleaning fluid for cleanliness. The cleaning fluid is the carrier used to extract particulate pollutants in the equipment. The cleaning fluid itself must not contain pollutants that affect the test result data. In order to ensure the cleanliness of the cleaning agent itself, the equipment is equipped with three levels of precision in series Filter device, the cleaning agent passes through a three-stage series filter device, the first stage uses 1μm pore size, the second stage uses 0.45μm pore size; the third stage uses 0.2μm multi-stage filter elements with equal pore size to filter, after the multi-stage filter element is filtered, the cleaning is guaranteed The liquid is clean before cleaning the parts.

Add cleaning agent/replace cleaning agent

The equipment is loaded with a capacity of 25L at a time; the matching cleaning fluid is automatically added to the equipment through the filling port. The user can choose the amount of addition according to the cleaning and testing needs. When the cleaning fluid needs to be replaced, select the corresponding control button to open the cleaning fluid discharge port The waste liquid is discharged automatically.

Intelligent man-machine control system

The intelligent man-machine control system is developed by German Siemens ten-inch full-color touch screen and PLC programming controller. The operation interface of the cleaning and extraction machine control software is simple, intuitive, convenient, fast. It can be quickly set and adjusted according to the cleaning requirements and parameters. One-button operation, each parameter can be displayed in real time on the same interface through the menu. In order to prevent the preset related parameters of the cleaning and extraction machine from being changed or mis-operated by very professionals, the software has authority protection for each parameter adjustment, and can perform multi-parameter and multi-program storage, and can quickly call the corresponding program for different products.

When cleaning, you can refer to different cleanliness testing standards, and use the menu-style program to adjust the cleaning time, cleaning spray pressure, cleaning time, spray flow and other corresponding parameters. According to the cleanliness of the product, the extraction procedure is detected, and the cleaning process is automatically controlled to meet different requirements. Product cleaning and extraction

Auxiliary lighting

Industrial-grade waterproof and explosion-proof LED auxiliary lighting, energy saving, environmental protection, safe and reliable, protection grade IP67.

Parameter

|

Items |

Index |

|

Pressure cleaning chamber size |

700*600*700mm (1600*1400*1600 optional, 2000*1600*2000 optional) |

|

Ultrasonic cleaning tank (optional) |

700*600*200mm |

|

Reservoir tank capacity |

25L |

|

Full color touch screen |

German SIEMENS 10-inch ultra-full color touch screen |

|

Three-stage circulation filtration |

1.0um, 0.45um, 0.2um three-stage circulation filtration |

|

Three-stage membrane |

One-click auto-clamping, specifications Ø47mm, Ø50mm, customized according to customer requirements |

|

Auto-lifting door |

One-click auto-constant speed lifting |

|

Special high cleaning pump |

Adopts Special high cleaning pump |

|

Cleaning chamber material |

8K mirror 304 stainless steel |

|

Programmable controller |

German SIEMENS digital programmable controller |

|

Full stainless cleaning water gun |

Full stainless custom, with cylindrical nozzle |

|

Cleaning collection pipeline |

Pipeline adopts food grade internal and external polished SUS304 one-time forming tube |

|

Main Function |

|

|

Auto-cleaning of the inner wall |

Auto-spraying and auto-cleaning of the inner wall |

|

Workpiece timing cleaning mode |

Cleaning time can be set arbitrarily |

|

Workpiece constant flow cleaning mode |

Flow rate: 0~8 L/min can be set arbitrarily, error rate ≤5% |

|

Manual cleaning mode |

Switch between manual cleaning and auto-cleaning at will |

|

Spray gun pressure setting |

Spray pressure 0-0.6Mpa can be set arbitrarily flushing pressure |

|

Real-time display of liquid level |

Real-time display of liquid level in the display screen |

|

Cleaning room lighting |

IP6 waterproof LED lighting |

|

Flow calibration |

Set permissions for flow calibration |

|

Auto-membrane holder |

One-click opening and closing, highly automated |

|

Filling/Draining |

Auto-program control, touch screen control |

|

Pipeline self-cleaning |

Through program control, auto-cleaning and drainage |

|

General parameters |

|

|

Standards |

ISO16232/VDA19/ISO18413 etc. standards |

|

System blank value |

Meet ISO16232-3 standard, self-cleaning degree ≤0.3mg/10um |

|

Flow range |

1.0L/min-8.0L/min, accuary5% |

|

Time setting range |

0-9999 S |

|

Applicable cleaning agent |

AP760, D60 solvent with flash point ≧62℃ |

|

Cleaning fluid filtration accuracy |

0.2um |

|

Applicable testing membrane |

Ø47mm (optional three-stage series filter membrane sample preparation sample preparation) |

|

Filter accuracy of air filter |

Meet the ISO14644-123 Class 5 standard, reach 0.3 μm. |

|

Working pressure |

>0.4Mpa |

|

Filter membrane clamp tooling |

Three filter membranes with different pore diameters can be placed at the same time to realize sample preparation of three-stage series filter membrane |

|

Vacuum filtration system |

Vacuum suction pressure:-(0.3 ~ 0.6) Mpa |

|

Power |

220V/50HZ |

Supply List

|

No. |

Item |

Specifications |

QTY |

Unit |

Remarks |

|

1 |

Cleanliness cabinets |

CC767 Component Cleanliness Cabinet |

1 |

Set |

Include in quotation. |

|

2 |

Cleaning spray gun |

|

1 |

Pcs |

|

|

3 |

Measuring glass |

|

1 |

Pcs |

|

|

4 |

Cleanliness cabinets precision filter |

0.22um/0.45um/1um, 156mm |

6 |

Pcs |

|

|

5 |

High-precision filter membrane |

5um、10um、20um |

1 |

Box |

|

|

6 |

Stainless steel flat tweezers |

|

1 |

Pcs |

|

|

7 |

Cleanliness cabinets air pipe |

|

1 |

Pcs |

|

|

8 |

Cleanliness cabinets grid shelf |

|

1 |

Pcs |

|

|

9 |

Device key |

|

1 |

Pcs |

|

|

10 |

Power cable |

|

1 |

Pcs |

|

|

11 |

Documents (Manual, QC) |

|

1 |

Set |

|

|

12 |

Electronic analytical balance |

|

1 |

Set |

Optional, not include in quotation. |

|

13 |

Electric drying oven |

|

1 |

Set |

|

|

14 |

Cleanliness cabinets cleaning agent |

D60 25L/ Pail |

1 |

Pail |

|

|

15 |

Laboratory glassware dryer |

|

1 |

Pcs |

|

|

16 |

Membrane preservation box |

|

1 |

Pcs |

|

|

17 |

Membrane clamp sealing ring |

|

1 |

Pcs |

|

|

18 |

Glass desiccator |

|

1 |

Pcs |