JYBO CleanTech cleanliness inspection process fully adheres to international cleanliness standards, including VDA19, ISO16232, and other industry standards.

JYBO CleanTech cleanliness laboratory is capable of Class 1000 cleanroom operation, and its Class 100 operation chamber.

JYBO CleanTech cleanliness inspection process fully adheres to international cleanliness standards, including VDA19, ISO16232, and other industry standards.

JYBO CleanTech cleanliness laboratory is capable of Class 1000 cleanroom operation, and its Class 100 operation chamber.

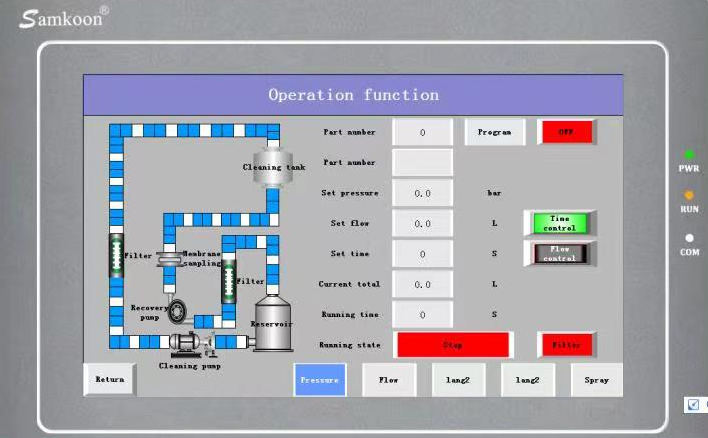

Step 1: Parameters Setting:

Before starting the extraction process, different parameters must be set based on the specific parts being cleaned and the cleaning method.

Standard Startup Parameters:

Pressure Rinsing: Flow Rate, Time

Ultrasonic: Ultrasonic Frequency, Power Density, Time

Shaking Rinsing: Filling Volume, Amplitude, Frequency, Time

Air Blow: Pressure, Blowing Time

Step 2: Particle Extraction:

Different extraction methods can be used for different components, including pressure rinsing, internal rinsing, ultrasonic, shaking rinsing, and air blowing. During extraction, workers must wear the instrument's included rubber protective gloves and use different nozzle types according to pre-set parameters to thoroughly clean the parts manually. The ergonomic design allows workers to better clean components, ensuring that no contaminants remain in any corners.

Step 3: Particles Collection:

After the extraction is completed, the particles will flow through the three-stage filter membrane together with the cleaning agent to separate the liquid and the particulate matter, thereby achieving the purpose of particle collection.

Step 4: Membrane Drying:

Place the filter membrane in a glass baking container and place them together in a professional drying cabinet to accurately remove moisture from the filter membrane and trapped pollutants, ensuring accurate data during subsequent weighing or analysis and avoiding moisture interference with test results.

Step 5: Membrane Cooling:

After drying the membrane, the glass baking container containing the membrane needs to be placed in a professional cooling cabinet to cool the membrane to room temperature in a constant, clean environment to avoid interference from environmental factors and ensure the accuracy of subsequent weighing or analysis.

Step 6: Gravimetric analysis:

After the filter membrane is completely dried and cooled, it is placed on a professional analytical balance for weighing. The difference in weight before and after the filter membrane intercepts pollutants can be accurately measured, thereby quantitatively determining the total amount of pollutants in the sample.

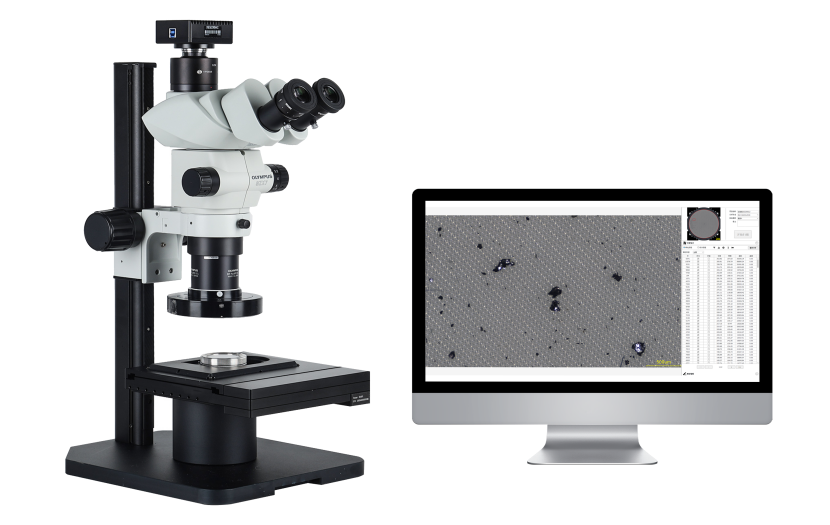

Step 7: Particle Analysis:

Place the dried and cooled filter membrane in the filter membrane fixing fixture, use a microscope to perform analysis and scanning, automatically identify metal particles, non-metal particles, and fibers, and generate a cleanliness test report with one click.