Categories

The Necessity of Cleanliness Testing

Sep 06 , 2025The Necessity of Cleanliness Testing

1. What is Cleanliness Testing?

Cleanliness refers to the degree of contamination of specific parts, assemblies, and entire devices. It can detect residual contaminants on the surface of parts or products after cleaning.

Cleanliness testing involves cleaning the surface of components using a specific method to collect contaminant particles. The contaminant particles attached to the filter membrane are then scanned using a microscope to determine the particle type, including metal, non-metal, fiber, size, and quantity. A cleanliness test report can also be generated with a single click.

2. Why do We Need to do Cleanliness Testing?

During the manufacturing, transportation, and operation of products, contamination, such as fine particles and non-volatile residues, is unavoidable. This surface contamination directly impacts product functionality, reliability, and even service life. Therefore, component cleaning is crucial for mass production and finished product quality control, especially in industries such as automotive, medical devices, and semiconductors.

Component cleanliness impacts product service life:

Contaminants can cause corrosion, wear, and seizure on the surface of automotive components, as well as short circuits and open circuits in electronic semiconductors, thereby shortening product service life. Cleanliness testing can effectively address this issue. Incorporating cleanliness testing into key steps of component production and assembly creates a closed-loop control system, preventing unqualified parts from flowing into the next stage or the customer, and preventing overall equipment failure caused by contamination of a single component. This indirectly ensures the long-term stable operation of the components and equipment, extending their service life.

Component cleanliness impacts product performance:

Contaminants and impurities can clog a vehicle's fuel system or enter the coolant of a liquid cooling system, reducing heat exchange efficiency. In severe cases, this can even cause safety hazards and dangers during product use. Cleanliness testing can proactively identify contaminants that could potentially impact product performance, preventing them from causing structural strength loss or functional failure. This can extend the product's overall trouble-free operation time and indirectly improve its long-term performance stability.

Component cleanliness impacts product after-sales costs:

Contaminants are ubiquitous in industrial production environments, impacting many industries, most notably the automotive, medical, electronics, semiconductor, and liquid cooling industries. The introduction of contaminant particles into these precision components can affect product performance and service life, increasing after-sales costs. Cleanliness testing prevents the risk of contamination-related failures, reduces the frequency of repairs and returns, and ultimately lowers all costs associated with after-sales service.

3. How to Conduct Cleanliness Testing

Cleanliness testing adheres to strict standards, with each industry having its own specific cleanliness standards. Examples include international quality standards such as AS9100 and GB/T39095 for the aerospace industry, and ISO 16232 and VDA 19.1 for the automotive industry. Only by strictly adhering to these standards can cleaning efficiency and reliability be guaranteed.

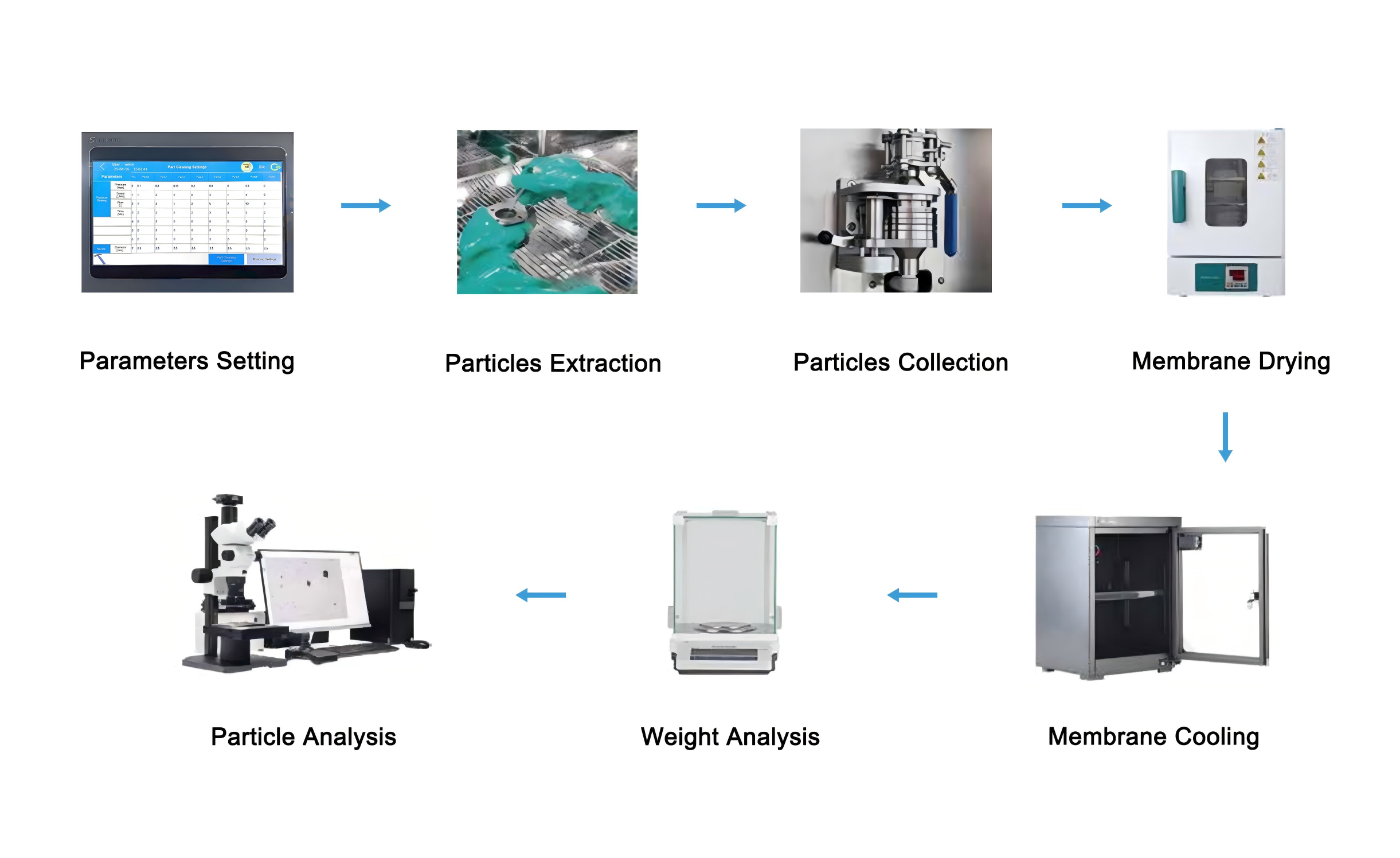

1. Parameter Setup: Before beginning extraction, different parameters must be set based on the specific parts being cleaned and the cleaning method.

2. Particle Extraction: Different extraction methods can be used for different parts, including pressure washing, internal perfusion, ultrasonics, shaking, and air purging. During extraction, personnel must wear the instrument's included rubber protective gloves and use different nozzle types to thoroughly clean the parts manually according to the pre-set parameters.

3. Particle Collection: After extraction, the particles, along with the cleaning agent, flow through the three-stage filter membrane, separating the liquid from the particulate matter, thereby achieving particle collection.

4. Membrane Drying: After collecting the particles, the filter membrane is placed in a glass baking container and placed in a specialized drying oven to precisely remove moisture from the membrane and the retained contaminants. This ensures accurate data during subsequent weighing or analysis and prevents moisture from interfering with test results.

5. Membrane Cooling: After drying the filter membrane, the glass baking container containing the membrane needs to be placed in a specialized cooling oven to cool the membrane to room temperature in a constant, clean environment. This prevents interference from environmental factors and ensures the accuracy of subsequent weighing or analysis.

6. Gravimetric Analysis: After the filter membrane is completely dried and cooled, it is placed on a specialized analytical balance and weighed. The difference in weight before and after the membrane retains the contaminants can be accurately measured, thereby quantifying the total amount of contaminants in the sample.

7. Particle analysis: Place the dried and cooled filter membrane in the filter membrane fixing fixture, use a microscope to analyze and scan, automatically identify metal particles, non-metallic particles, and fibers, and generate a cleanliness test report with one click.