According to VDA19.1, ISO16232 and internal standard.

Unrestricted by product weight with a maximum weight of 200kg.

360-degree flushing ensures no contaminants remain in any corners.

Unrestricted by product size and easy to operate.

Widely adjustable flow rate range.

Provide customized services to meet all testing requirement.

Summary

CC-IR component cleanliness cabinet used for cleaning and extracting particles from components integrates spray cleaning, ultrasound, perfusion flushing, side wall spray self-cleaning, membrane sample preparation (particle extraction), online filtration and recovery of cleaning agents, and circulating fine filtration into one.

CC-IR component cleanliness cabinet is equipped with many other function including real time display of equipment working status, idependent operating space with a built in air laminar flow system, automaticcollection of filter membrane samples.

The wet extraction system, the most commonly used extraction method, covers a large portion of the requirements for particle extraction from components.

Application

The advent of the internal rinsing method has solved the problem of cleaning parts with internal structures. It can be specifically used to clean the inner surfaces of the tested parts, and features a wider range of applications, higher cost-effectiveness, and more objective extraction results.

It is mainly applied in the medical and health industry, precision manufacturing and electronics industry, food and beverage industry, biopharmaceutical industry, as well as the automotive and machinery industry.

Features

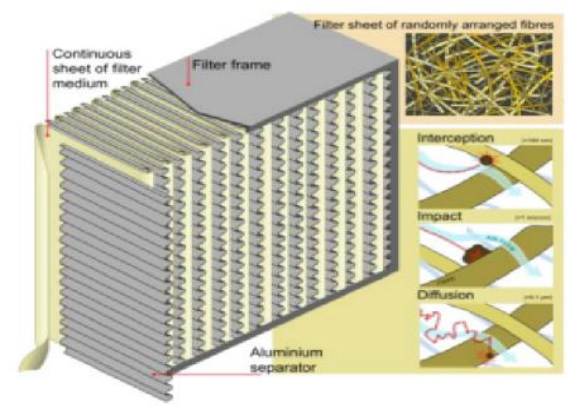

Laminar air purification

The equipment integrates an air supply device with air circulation filtration function. Create a clean space with class 1000 or 100 in the cleaning work area (with a standard laboratory air level of millions), providing a good cleaning operating environment for component cleanliness testing, and reducing the impact of external environment on testing results.

Four wall spray self-cleaning

The upper area of the equipment pressure cleaning chamber is equipped with multiple wide-angle nozzles, which can automatically clean the four walls of the pressure cleaning tank and prepare for the experiment in the early stage.

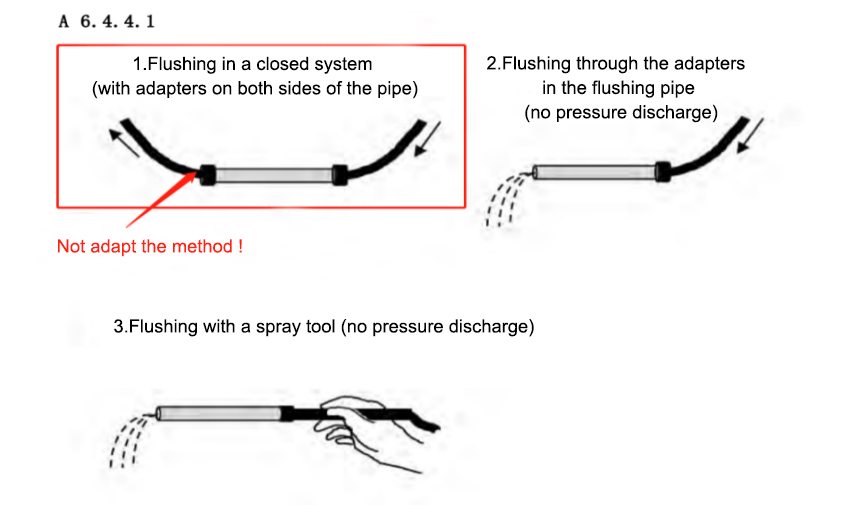

Internal Flushing

The equipment reserves pipeline access ports for perfusion flushing of components.

The perfusion liquid return port is placed inside the equipment chamber, instead of being directly connected to the filter membrane sample preparation, which avoids the vacuum in the chamber caused by the direct connection of the liquid inlet and outlet to the filter membrane sample preparation, as well as the flow resistance caused by issues with the filter membrane pore size, thus preventing incomplete particle collection.

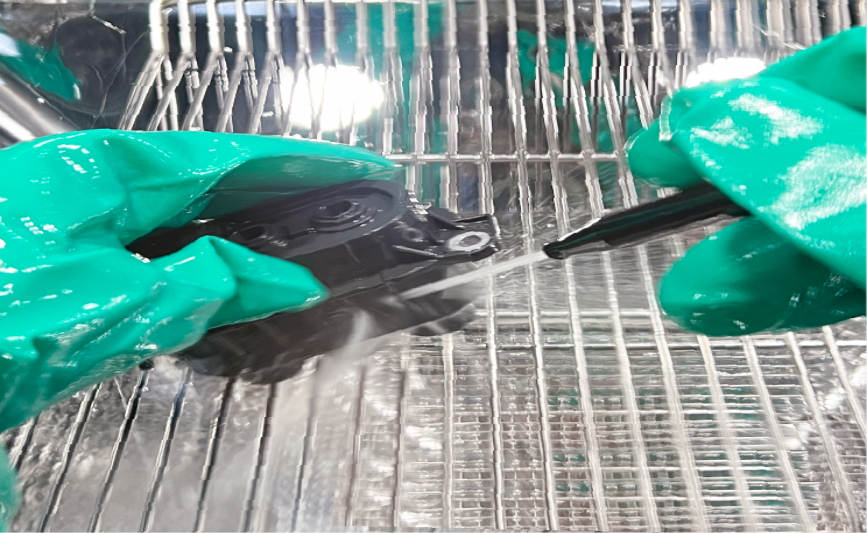

Example of cleaning in the flushing and cleaning process

Pressure/flow rate flushing

The components are inspected with a spray gun set at a certain pressure or flow rate, angle, and then extracted and collected residual particles. The spray cleaning pressure (National standard) or flow rate (European standard) can be set, and the operation can be carried out in a quantitative or timed manner with a set flow rate. The specific requirements are based on the cleanliness operation specifications of different components.

Filter membrane sample preparation device

The cleaning agents after cleaning the components can be synchronously and automatically filtered and recycled through an online filter, and then timely collecting particulate contamination on the surface of the components in the cleaning agents to the surface of the detection filter membrane. No need for manual operation to filter cleaning agents.

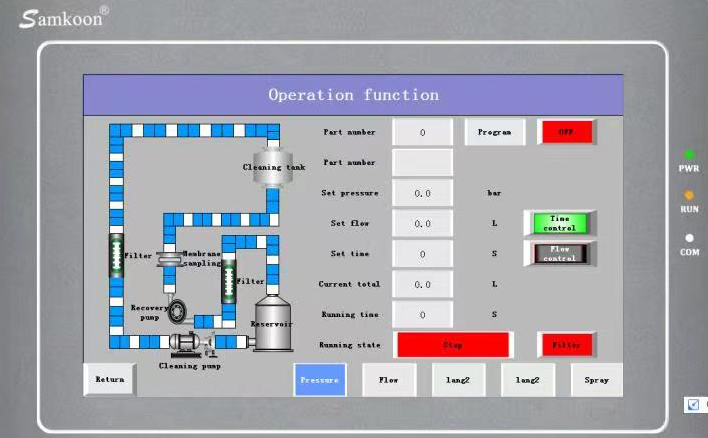

Cleaning parameter settings

The storage cleaning parameters of cleaning pressure, flow parameters, flow rate settings, cleaning time, cleaning mode can be adjusted according to different cleanliness detection standards.

Liquid filtration system

Install two liquid filters inside the equipment, and the cleaning agents is discharged from the storage tank through a pressurized pump. It passes through a 0.2 micron precision filter element to ensure that the liquid used for components cleaning is clean. Before returning the cleaning agent to the storage tank through the membrane sample preparation, it is filtered by 1.0um to ensure that the liquid in the storage tank is clean.

Add/replace cleaning agent and alarm function

The capacity of the equipment liquid storage tank is 50l; the matching cleaning agents is automatically added to the inside of the device through the dispensing port. Users can choose the amount to add according to their cleaning and testing needs. When the cleaning agents needs to be replaced, select the corresponding control button, open the cleaning agents discharge port, and the device will automatically discharge the used cleaning agents.

And there is an internal consumables replacement cycle setting function, which sets cycle reminders based on user specific needs for consumables replacement.

Work status prompt

Real time display of current working status, current flow rate, total amount of cleaning agents, cleaning mode, and other information. Real time monitoring of working status. When encountering an error, the device automatically stops working and sends an alarm prompt, displays current error information, and provides help methods for solving problems.

Fine filtration cleaning agents

The equipment uses a dedicated cleaning agents for cleanliness, which is the carrier used to extract particulate contamination from the equipment. The cleaning agents itself must not contain contamination that affect the detection results. The equipment integrates an automatic precision filtering cleaning agents function to ensure that the cleaning agents is clean before cleaning the components. The cleanliness of the cleaning agents can be checked through the terminal filtration device.

Auxiliary lighting

Industrial grade explosion-proof led auxiliary lighting is energy-saving, environmentally friendly, safe and reliable, with a protection level of IP67.