Categories

Latest blog

Monel400, N04400 Monel alloy knowledge explained in detail

Feb 01 , 2024Monel400, N04400 Monel alloy knowledge explained in detail

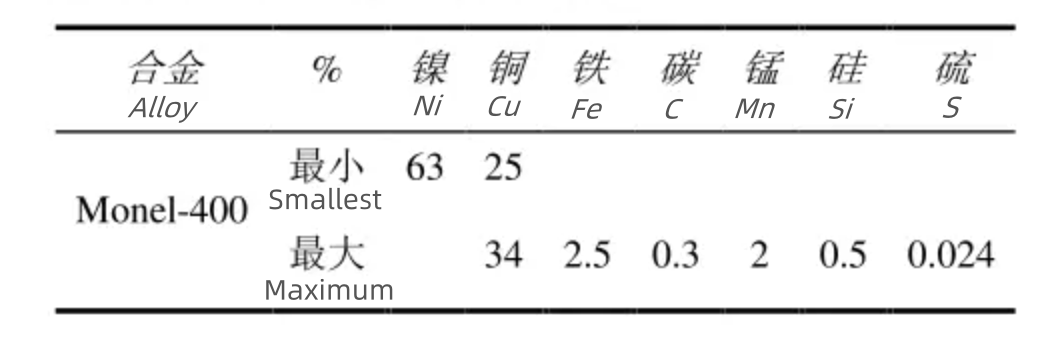

Monel-400 alloy and its weldability Monel-400 alloy Monel-400 alloy is a single phase austenitic alloy with nickel as the main metal (containing about 63% nickel) and copper as the auxiliary metal (containing about 25% copper). The alloy is a deformable nickel-copper series nickel-based corrosion resistant alloy, which not only has excellent physical properties such as high strength, high corrosion resistance and wear resistance in a wide temperature zone (to 1000F), but also has good properties such as easy forming, easy brazing and easy cutting. Therefore, it is widely used in cutting-edge industries such as petrochemical industry, nuclear industry, national defense industry and other industries with high strength and high corrosion resistance under complex environmental conditions, and important parts made of the alloy material can greatly increase the overall service life of the container. The chemical composition table of Monel-400 alloy is shown as follows:

Monel-400 alloy has excellent corrosion resistance to reducing media [6], under normal circumstances, it is more resistant to the corrosion of reducing media than pure nickel, especially in hydrofluoric acid and alkali solutions, the stability is more prominent, only less than platinum, silver. It has good stability in many corrosive media such as hydrofluoric acid, alkali, seawater, H2S, H2SO4, H3PO4, organic acid, etc. Monel-400 alloy can resist the corrosion of anhydrous ammonia and ammoniating conditions below 585℃ due to its high nickel content. Monel-400 is one of the few important materials that can resist hydrofluoric acid, and it is resistant to corrosion in sulfuric acid at a concentration of less than 85%. In most cases of seawater corrosion, the corrosion rate of Monel-400 alloy is less than 0.025mm/a. The corrosion rate of Monel-400 is less than 0.026mm/a in high temperature steam.

Monel-400 alloy is a solid solution reinforced alloy, with excellent weldability, commonly used welding methods, such as: electrode arc welding, gas shielded welding and other welding methods can be applied. Due to the large nickel and copper composition of Monel-400 alloy, the welding metal is generally used in the welding process with the same chemical composition of the base metal solder, the general wire selection of ERNiCu-7, the electrode selection of ENiCu-7. In the welding process, due to some of the thermal physical properties of Monel-400 alloy, such as the thermal conductivity (21.744 W/mK) is good, resulting in thermal cracks, pores, non-fusion and other defects in the welding process.

JYBO Instrument has made a detailed study on the weldability of Monel-400 alloy. We believe that the reason for hot cracks in welded joints in Monel alloy welding is that the segregation of S leads to the easy formation of NiS low-melting point eutectic, and inter-crystal cracks are easy to form under the action of welding stress. And the silicate formed by Si is easy to form high temperature and low plastic cracks. As for the formation of stomata, we believe that the welding stomata of Monel-400 alloy have H 2O stomata, H 2 stomata and CO stomata, but mainly H 2O stomata. The main reason for the formation of H2 pores is that when the welding pool solidifies, with the decrease of oxygen solubility, the liquid nickel that dissolves a lot of oxygen releases oxygen to combine with hydrogen, and the formed H2 has no time to escape to form a porosity. The rapid temperature drop of the weld and its vicinity during the welding process also leads to the formation of more H2O pores in these areas.

To prevent the occurrence of hot cracks, smaller welding current and larger welding speed should be selected to reduce the heat input, because the heat generated by the arc is not easy to disperse during the welding process, easy to form overheating, resulting in coarse grains, so that the intercrystalline interlayer thickening, which will weaken the intercrystalline bonding force, resulting in the formation of hot cracks; Strictly control the interlayer temperature, which can control the infiltration of S and P elements, reduce the easy accumulation of low-melting point eutectic (Ni-S eutectic Ni-P eutectic) at the grain boundary, because these isomelting point eutectic low strength, brittle-high, more prone to thermal cracks.

In order to prevent the generation of pores, alkaline low-hydrogen electrode should be used, fully dried before welding, DC reverse welding, welding groove clean, and the oil, lubricant, moisture and other substances within 50mm on both sides of the groove clean, and then welding after clean. At the same time, the deoxidizer can be properly added to reduce the oxygen content without affecting the welding quality.

In general, for the welding process of Monel-400 alloy, the main points are to select a suitable welding method, reserve a large welding groove, reduce the blunt edge, strictly clean the weld and its nearby area before welding, eliminate the source of cracks and pores, and conduct proper preheating during welding to reduce the heat dissipation rate of the weld pool. Use the appropriate mode of operation, select the appropriate welding process parameters, etc.