Categories

Latest blog

The role of curve drift correction

Dec 29 , 2025The role of curve drift correction

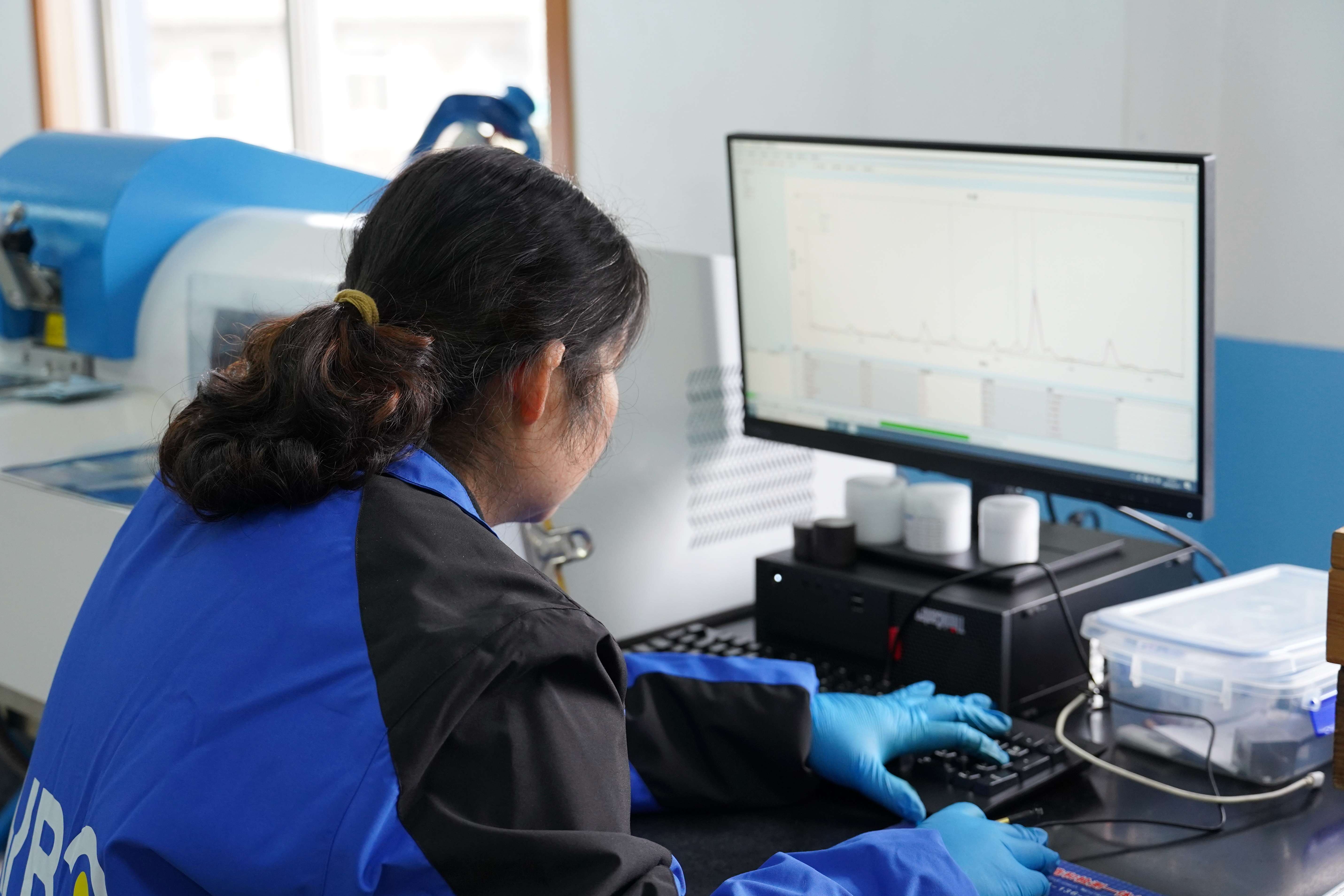

The operation process of the photoelectric direct reading spectrometer consists of steps such as startup, sample measurement, and shutdown. The steps of measuring samples include establishing control methods, determining control samples, measuring samples, and printing reports.

In the photoelectric direct reading spectrometer, dozens of different substrates and types of working curves are stored in the instrument software, and these working curves and their parameters have been set before leaving the factory. In theory, these curves are permanent. For analysts, it is not necessary to master the process of drawing work curves. But in normal use, regular drift correction or curve standardization of these curves is necessary to ensure their permanent use. In material analysis, analysts can select appropriate working curves and standard samples based on the type and grade of the material, and use sample control analysis to complete the detection and analysis of the sample.

The core function of curve drift correction (curve standardization) is to offset the deviation of the working curve caused by various interference factors during instrument operation, maintain the accuracy of curve factory calibration, ensure the long-term stability and usability of the working curve, and ensure the accuracy and reliability of sample detection results. It can be specifically divided into the following four points:

1. Offset the curve deviation caused by the changes in the instrument's own state and stabilize the basic accuracy of the curve: During the long-term operation of the photoelectric direct reading spectrometer, the internal core components (such as the light source, grating, detector) will undergo subtle changes in state with the use time and environmental fluctuations (such as attenuation of light source intensity, drift of detector sensitivity, and decrease in grating spectral stability). If not calibrated, the originally calibrated working curve will deviate from the initial reference, resulting in distortion of the correspondence between the curve and the actual spectral signal. Drift correction can be used to reverse calibrate the instrument through the known component signal of the standard sample, correct the curve deviation caused by the changes in component state, and return the curve to the accurate reference, maintaining the curve accuracy set by the factory.

2. Offset the curve deviation caused by external environmental interference and reduce the impact of the environment on detection: Changes in temperature, humidity, and air pressure in the instrument's operating environment can indirectly affect the collection and transmission of spectral signals (such as temperature fluctuations changing the physical properties of components and air pressure changes affecting the spectral transmission path), leading to unexpected drift in the working curve. Even if the factory parameters of the curve remain unchanged, it cannot match the actual detection scenario in the environment. Drift correction can be combined with the detection signal of standard samples in the current environment to adjust the curve parameters, offset the deviation caused by environmental interference, adapt the curve to the real-time usage environment, and avoid detection errors caused by environmental factors.

3. Ensure that the work curve is theoretically permanently usable and reduce the cost of curve redrawing: The article clearly states that the work curve is theoretically permanently valid, but it relies on regular drift correction - if no correction is made, the curve drift will accumulate over time, the deviation will gradually expand, and eventually lose calibration value, requiring redrawing of the work curve (the redrawing process is complex and requires a large amount of standard samples, which is time-consuming and labor-intensive). Regular drift correction can continuously correct curve drift, maintain the adaptability of the curve to detection requirements, and truly achieve long-term cyclic use of the working curve. It does not require analysts to master the curve drawing process and can also avoid the additional cost of redrawing the curve.

4. Support the precise implementation of control sample analysis method to ensure the reliability of sample detection results: Analysts need to complete the detection through "selecting corresponding working curves+matching standard samples+control sample analysis". The core logic of control sample analysis method is to rely on accurate working curves, compare the spectral signals of standard samples and test samples, and deduce the composition of test samples. If the working curve deviates from the benchmark due to drift, even if the parameters of the standard sample are known, the curve cannot establish an accurate correspondence between "signal component", which will lead to the failure of the control sample analysis logic and the deviation (high/low) of the test results of the sample to be tested. Drift correction can maintain a precise "signal component" correspondence in the working curve, providing reliable support for sample control analysis methods and ensuring that the final sample detection results conform to the actual composition, meeting the accuracy requirements of material analysis.